views

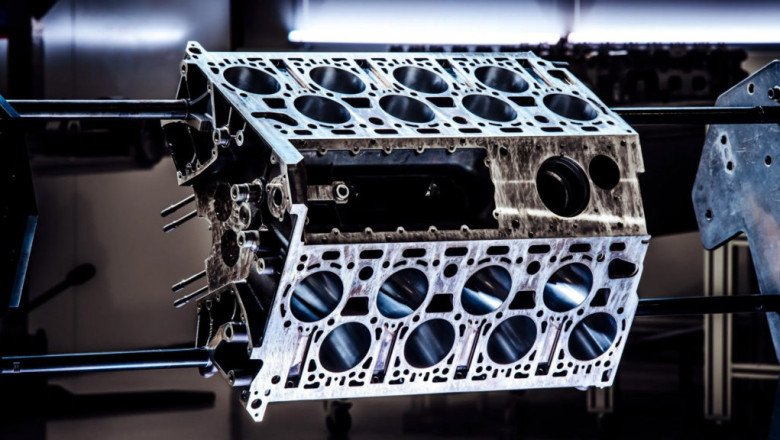

An engine block, also referred to as a cylinder block, is the main element of an internal combustion engine. It accommodates the cylinder, piston, and other critical engine parts. Engine blocks can be categorized based on various factors, including their material, configuration, and design.

Think of it like this: if the engine block is one side of a coin, then the other side is the engine head. The engine head sits on top of the engine block and is responsible for the generation of power inside the combustion chamber of an engine. Read the linked article to know completely about the engine head and its components in an internal combustion engine. Back to the engine block.

As mentioned earlier, the engine block houses several components that are responsible for transmitting the power from the combustion chamber to the gearbox via a piston, connecting rod and a crankshaft arrangement. However, the block itself is a large metal-based structure to hold various components in place.

Engine blocks can be made from a variety of materials, each with its own set of advantages and disadvantages. The choice of material often depends on factors such as cost, weight, durability, heat resistance, and manufacturing processes. Here are the most common materials used to make engine blocks:

Engine blocks are typically manufactured through a process known as casting, which involves pouring molten metal into a mould to create the desired shape. The casting process can vary depending on the type of material used and the specific design of the engine block.

These are round, cylindrical bores for the pistons to move up and down in. The number and arrangement of cylinders such as inline, V-shaped, or flat determine the engine’s configuration.

Pistons are components that fit inside the cylinders. They move up and down within the cylinders to compress the air-fuel mixture during the intake and compression strokes and convert the energy of combustion into mechanical motion during the power and exhaust strokes.

Piston rings are circular metal rings fitted around the pistons. They help seal the gap between the piston and the cylinder walls, preventing excessive leakage of gases and oil. They also assist in heat transfer from the piston to the cylinder walls.

The crankshaft is a long, rotating shaft located at the bottom of the engine block. It converts the linear motion of the pistons into rotational motion, which is then transferred to the transmission and ultimately to the wheels.

Connecting rods, also known as con rods, link the pistons to the crankshaft. They transmit the reciprocating motion of the pistons to the rotating motion of the crankshaft.

It is the primary bearing to support and position the crankshaft within the engine block. They reduce friction and wear between the rotating crankshaft and the stationary block.

The camshaft is a shaft with eccentric lobes or cams that control the opening and closing of the engine’s valves. It is responsible for timing the valve functions. The camshaft is mostly placed inside the head of modern engines. However, older pushrod engines had the camshaft placed inside the engine block.

These are metal plugs placed in openings on the engine block to allow for the removal of sand cores used during the casting process. They are also called freeze plugs because they can help prevent damage to the block if the coolant freezes and expands.

The engine block contains various passages for circulating engine oil to lubricate moving parts, cool components, and remove heat from the engine.

Engine blocks have channels and passages for circulating coolant or antifreeze to regulate engine temperature and prevent overheating.

The crankcase is the lower portion of the engine block that houses the crankshaft, connecting rods, and crankshaft bearings. The bottom end of the crankcase serves as the oil reservoir for the engine’s lubrication system.

Engine blocks can be categorized based on various factors, including their material, configuration, and design. Here are some common types of engine blocks:

Example: 2023 Toyota Corolla

Configurations: In-line 2 (Parallel-Twin), In-line 3, In-line 4, In-line 5, In-line 6

Example: 2023 Ford Mustang GT

Configurations: V4, V6, V8, V10, V12

Example: 2023 Porsche 911

Configurations: Flat-2, Flat-4, Flat-6

Example: 2023 Bugatti Chiron

Configurations: W8, W12, W16

Example: 1933 BMW 132

Configurations: Single, Double, Star

Experimental Engine

Example: 2012 Mazda RX-8

Configurations: One, Two, Three & Four Rotors

These are some of the common engine block configurations found on an internal combustion engine for cars. As mentioned earlier, the engine block plays a vital role in the generation of power in an internal combustion engine along with the engine head.

Here is your comprehensive overview of the engine block of an internal combustion engine. Stay tuned to the DubiCars Blog section for upcoming in-depth articles covering various other components of the internal combustion engine. Here is a beginner’s guide to generic automotive terms.

Looking to own a car? Here is a list of used cars on sale in the UAE and new cars on sale in the UAE.

https://www.dubicars.com/news/get-to-know-your-car-better-a-detailed-guide-to-automotive-terms-engine-block.html

Comments

0 comment